OUR PRODUCTS

CUSTOM TANKS,

WE'VE GOT YOU COVERED.

While we offer a broad range of stock tanks, we excel at unique designs. Bring us your specifications and questions. Our engineers work with you through the entire process – from design and prototype construction to fabrication and delivery.

Getting a quote is quick and easy.

Just provide as much info as you can.We’ll do the rest.GET A QUOTE

OUR CAPABILITIES

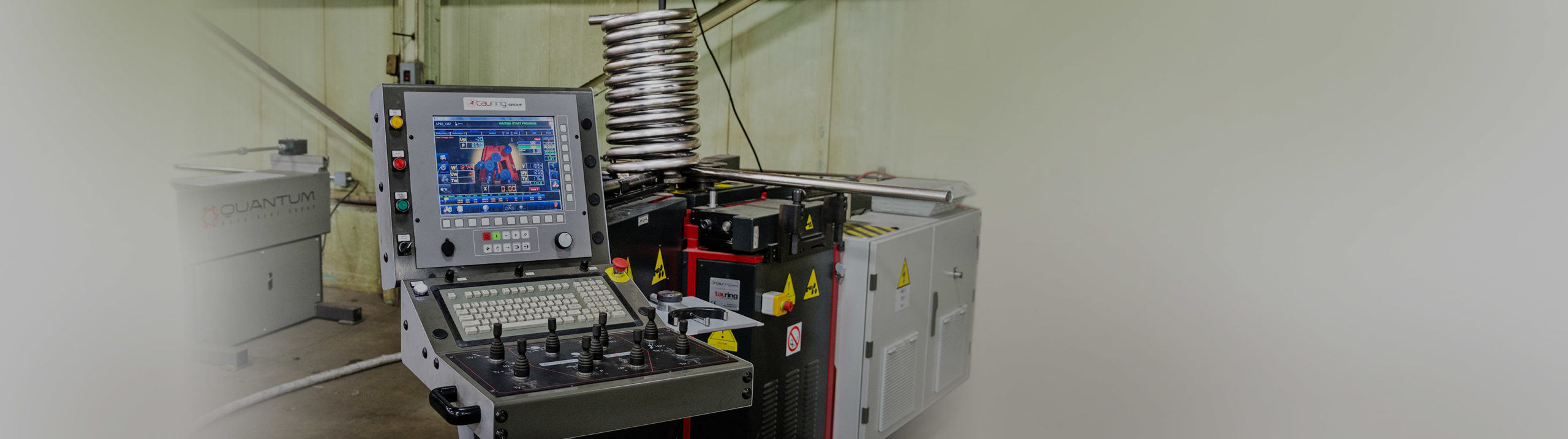

Our Michigan campus is equipped to design and fabricate tanks in carbon steel, stainless steels, and a variety of specialty metals for specific applications. This includes our 85,000-square foot Alloy Works®, which gives you access to an expansive array of stainless steel tanks and piping designed for superior strength, corrosion resistance and performance.

Everything required to meet your demands — from engineers with vast customization experience to non-destructive testing and evaluation — is here on-site. That’s why so many industries count on the quality of Niles Steel Tank.

Solutions for

Niles Steel tank Videos

Niles Steel Tank

Niles Steel Tank Alloy Works®

Microban® antimicrobial product protection helps prevent the growth of bacteria, mold, and mildew that may affect the product. The built-in antimicrobial properties do not protect users or others from disease-causing organisms. Microban® is a registered trademark of MIcroban Products Company.

#nilessteeltank

#nilessteeltank